With my latest post I started a series of blogs that report on the discussions of former partners of the Learning Layers (LL) project on the impact of our work. This was triggered by reports that the key result of our work – the Learning Toolbox – is being used in the original pilot context (training for construction work) and is getting new users. In particular this discussion was inspired by the fact that such tools gain new importance in the period of corona crisis, when schools and training centres are closed and traditional conferences are being cancelled. In my previous blog I gave a brief overview on the discussions that we have had and on the joint paper that we have been preparing. In this blog I will summarise some key points that I and my co-author Gilbert Peffer have raised on the case that we have presented – the use of Learning Toolbox (LTB) in the training centre Bau-ABC Rostrup. Below I will use our draft text (that was shaped as responses to given questions) as a slightly edited version.

The pioneering Case: Learning Toolbox in the training centre Bau-ABC Rostrup

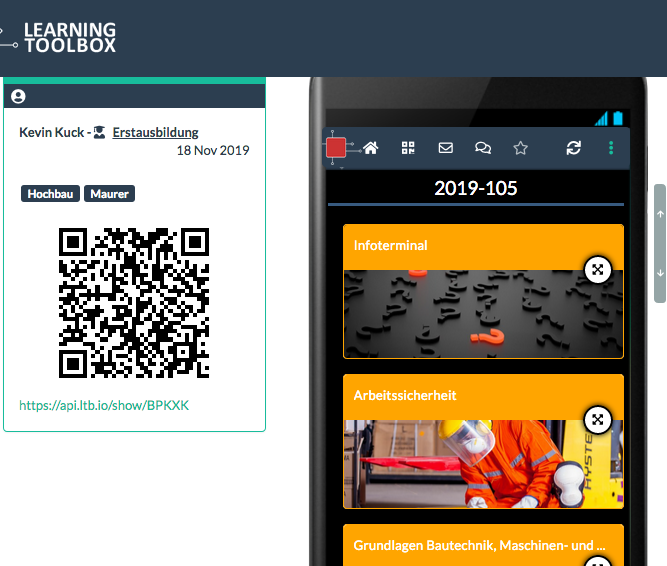

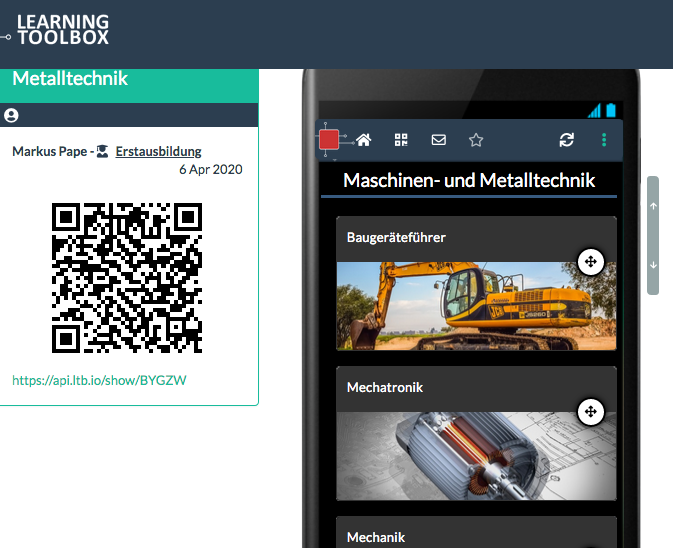

The Learning Toolbox was developed in the Learning Layers project as a response to the needs of the training centre Bau-ABC Rostrup (a major application partner from the construction sector). The initial design idea referred to digitisation of training materials, instruction sheets, project reporting sheets and self-assessment procedures. However, in the course of iterative co-design cycles, the process took the course towards shaping an interactive toolset to support training and learning activities.

What particular problems were addressed in the co-design process?

In Bau-ABC Rostrup the apprentices spend relatively short periods (one or two weeks at a time) and are trained by full-time trainers who are Meisters (master craftsmen) in their trade. During each period they complete a project in the respective trade. Then, they move back to their companies or have another training period in a supporting trade. In general, the projects are based on genuine work tasks that are implemented in a workshop or at outdoor training areas.

Previously, the instructions for the apprentices’ projects had been provided orally with the help of instructive worksheets (for preparing the project plans). Likewise, the reporting on the projects was done manually. In principle, the project cycle was based on self-organised learning – independent search for knowledge resources, drafting the plan plan, reporting the implementation and then assessing the outcome. The functionality of Learning Toolbox – based on trade-specific stacks that consisted of different tiles – provided support for learning when completing the work tasks.

Stakeholders who have been involved in the co-design process and pilot activities

The co-design work was carried out as a collaborative process by researchers, technical partners and full-time trainers from Bau-ABC. During an earlier phase of the work the project team provided basic multimedia training for some voluntary trainers. At a later phase the project team and these trainers provided an intensive training campaign for all trainers of the training centre. In the pilot testing of the Learning Toolbox a core group of trainers introduced the toolset in their training and results were monitored by the project team. Also, at the final phase of the project, the use of the Learning Toolbox as support for construction work processes was demonstrated for several craft trade companies. As a result, follow-up processes (feasibility studies and project initiatives) were started with some companies.

How have the training practices been changed and what new practices have emerged?

The functionality of the Learning Toolbox was easy to be customised for different training purposes and according to the pedagogic priorities of the trainers. Thus, it made it easier for the trainers to emphasise independent searches among a wide range of web resources. (This was essential for borehole builders who were working alone on remote construction sites). Also, it made it possible to give learners a gradual access to a wider range of resources (and to solutions of their peers) once they had learned to develop their own solutions to the project tasks. (This was essential for the road-builders and pipeline-builders.) Moreover, apprentices were encouraged to document their projects with the Learning Toolbox. This enabled the instructors to see progress of their apprentices in real time and provide more timely feedback. The LTB has also strengthened the self-organisation of the instructors in terms of streamlining their content and sharing common resources between the different professions. While this approach to collaborative training was already there at Bau-ABC, the LTB offered a further channel to systematise this practice. Altogether, the co-design process has been characterised by a continuing research & development dialogue that has been underpinned by the accompanying research approach of the research institute ITB, University of Bremen.

What has been the impact so far and what can be expected in the near future?

After the project the use of the Learning Toolbox was spread across all trades in which Bau-ABC Rostrup provides apprentice training. Consequently, the apprentices have started to complete their projects with the help of the Learning Toolbox. Based on this pioneering case, other German training centres in the construction sector are in the process of adopting the Learning Toolbox both for initial VET and for continuing VET. There are also teacher groups at a number of medical faculties in Germany who have adopted the LTB for practice training. Due to the closure of the training centres because of the COVID19-epidemic the trainers of Bau-ABC Rostrup have prepared trade-specific stacks with the Learning Toolbox to support independent learning.

What have been key aspects for sustaining this initiative so long after the project

Altogether, the co-design process, the piloting phase and the follow-up phase have been characterised by intensive research & development dialogue (underpinned by an accompanying a research approach that dovetails with the co-design process), adjustment of the tool development to the pedagogic approach of the trainers and to the effort to promote self-organised learning of apprentices. In addition, the project work and the follow-up has been characterised by strong support from the accompanying researchers of ITB. Furthermore, the trainers of Bau-ABC have become strong multipliers of innovation both within their organisation and in their networking with other training centres and partner companies. At the end of the project it was not certain, how the innovations could be sustained and spread. In the construction sector it was essential that the developers of the Learning Toolbox and the accompanying researchers from ITB took several initiatives to launch follow-up activities with construction companies.

I think this is enough on this case study. The next post will give insights into other cases that were explored in our discussions.